How to Prevent A/C Evaporator Coil From Leaking Freon

Refrigerant, commonly referred to as Freon, is essential to the functioning of your air conditioning system. Your air conditioner pumps refrigerant around, absorbs heat from inside your home, and releases it outside to produce cold air. If your refrigerant levels are even slightly low, your home may produce cold air, but the system will use more electricity, remove less humidity, and over-heat the compressor. Circulating refrigerant efficiently is absolutely crucial for maintaining the cooling capacity of your AC unit.

Evaporator coil leaks are the most common type of refrigerant leak and can be detrimental to your entire HVAC system, reducing performance, energy efficiency, and your home’s comfort level. We’re here to guide you through practical steps you can take to improve your overall indoor air quality and prevent evaporator coil leaks. We’ll also discuss the new manufacturer designs that are helping improve the life of your coil.

Preventing Freon Leaks Start With Knowing the Root Cause

Understanding the causes of evaporator coil leaks is crucial for preventing them. As we outlined here, the most common cause of an evaporator coil leak is formic acid that forms on the coil from volatile organic compounds in your indoor air. Over time, this mild acid attacks the copper tubing in the evaporator coil, creating many microscopic pinhole leaks.

Overall, indoor air pollutants fall into four main categories: dust, unhealthy humidity levels, biological contaminants like mold and bacteria, and Volatile Organic Compounds (VOCs). This last category includes the chemical Formaldehyde, which contributes to the majority of evaporator coil leaks. This can be found in many household products like cleaning products, air fresheners, newer furniture and carpet, and cigarette smoke. Exposure to these chemicals i causes an evaporator coil to corrode prematurely.

By reducing the levels of VOCs in your home, you can both prevent expensive coil leaks and ensure a healthier living environment for you and your family. Follow these proven strategies to prevent leaks and ensure your air conditioner runs smoothly for years to come.

Reduce VOCs With the APCO UV System

The average home is eight times more polluted than outdoors. You can reduce chemicals in your home by using natural cleaning products and opening windows. However, in the Miami Valley, we have only a few days a year nice enough to open the windows for fresh air. In our experience, the most energy efficient way to reduce chemical contaminates in your home is to capture them with activated charcoal. While you can buy charcoal air filters, they are can be expensive and they must be replaced every month.

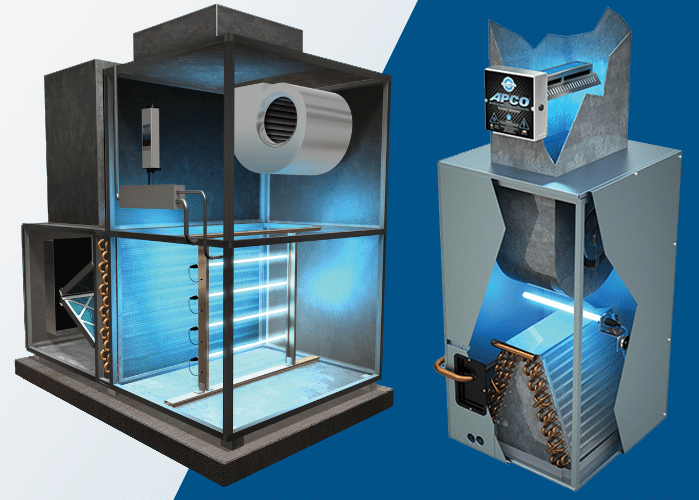

Our favorite tool to absorb VOCs is the APCO UV air purifier. In addition to a germicidal UV-C light, it has a sort of filter that is a combination of catalyst and charcoal that is constantly bathed in UV-C light. This chemical air filter absorbs VOCs and holds them in place while the UV-C light neutralizes them. It basically converts formaldehyde into water and carbon dioxide. This continuous process of capturing and oxidizing pollutants significantly reduces airborne chemicals and formicary corrosion in your AC coil.

There are countless UV lights on the market that don’t do much except make your ductwork glow. The APCO system’s unique blend of powerful UV-C, oxidizing catalyst, and activated charcoal make it an amazing tool to improve indoor air quality. The germicidal properties of the UV-C light are just a bonus.

Installed directly into your home’s air handler system, the APCO UV light ensures continuous air purification and efficient production of cool air with very little maintenance. It comes equipped with a long-lasting 3-year bulb and a self-cleaning carbon filter that never needs replaced. Who know you could create healthier indoor air AND decrease the risk of leaking refrigerant at the same time!

Fresh Air Ventilation and Energy Recovery Ventilators

As we build our houses tighter and tighter with insulation, an unintended side effect is that we prevent dilution of our contaminated air. Every time we spray cleaning products, much of the chemicals evaporate into the air and don’t go anywhere as long as our windows are closed. Every time we clean, the air in our home gets dirtier. Essentially, we seal ourselves up in a room full of VOCs.

Improving fresh air ventilation is a critical strategy for maintaining overall air quality and preventing an AC evaporator coil leak. In the IAQ industry we say, “The best solution for pollution is dilution.” Just open your windows!

A well-designed ventilation system works like an open window to increase the flow of outdoor air into your building, diluting while expelling harmful indoor pollutants. By decreasing the concentration of corrosive chemicals and VOCs, you are proactively preventing coil leaks caused by corrosion.

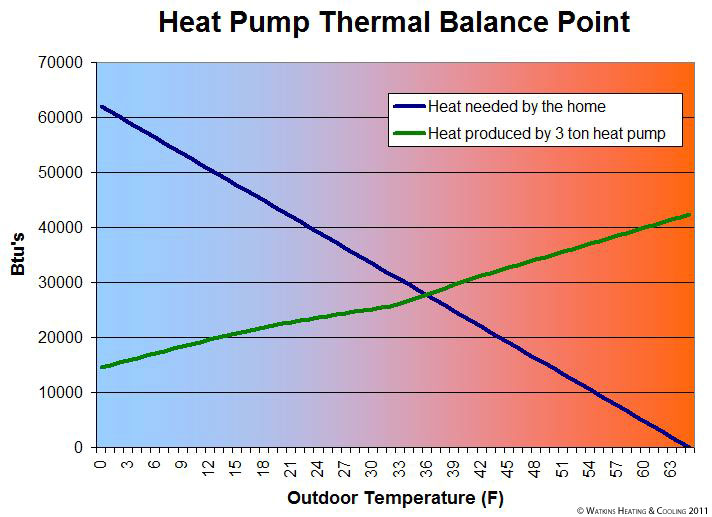

The reason fresh air intakes are rare in Ohio is the energy cost to heat and cool so much outdoor air. An Energy Recovery Ventilator (ERV) solves this problem by combining intake and exhaust in one air handler. Both air streams pass through a core than exchanges heat and humidity between indoor and outdoor air. By introducing balanced ventilation systems, you salvage up to 80% of the energy that would be lost if you just opened your windows year round. In short, an energy recovery ventilator ensures continuous fresh air without huge energy costs.

Whether you use an APCO air purifier or an ERV, reducing indoor VOCs will reduce formicary corrosion and extend the life of your air conditioner’s evaporator coil.

How A/C Manufacturers Are Reducing Evaporator Coil Leaks

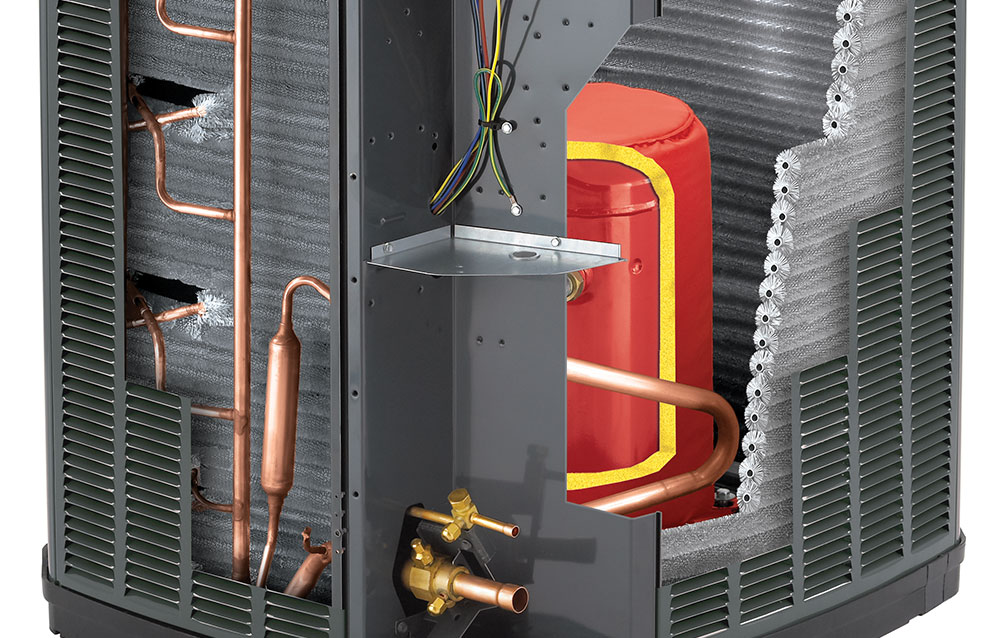

As we explained in our article about the causes of AC evaporator coil leaks – the thin copper tubing in your indoor unit’s evaporator coil is vulnerable to formicary corrosion. The excellent workability and thermal conductivity of copper makes it a preferred choice for making high efficiency heat transfer coils.

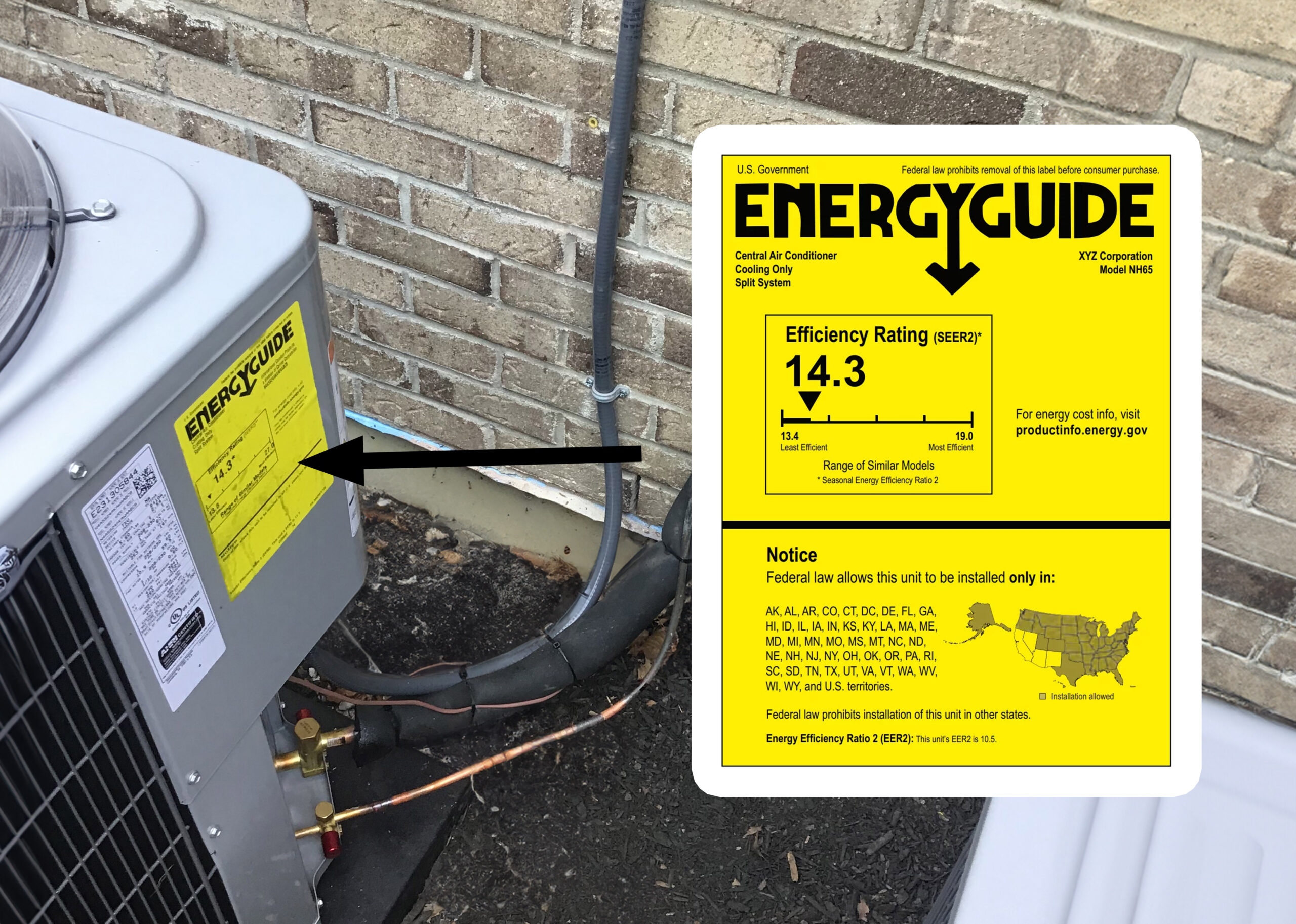

Thinner Copper Evaporator Coils Leading to Premature Failure

Coil corrosion is an inescapable reality of copper/aluminum coils, but it seems to have gotten worse in the last decade. To hit the new efficiency standards in 2007, manufacturers began using thinner copper which transfers heat faster. It also helped that using less material lowered their costs. Air conditioners built in the 90s with thick copper coils were still subject to formicary corrosion. However it took longer for the organic acids in the air to drill holes through the thicker HVAC tubing and cause a leaky evaporator coil.

With the thinner copper in newer units, it has become fairly common to see leaks within 5 to 10 years. Nearly all air conditioner manufacturers have dealt with issues with their copper coils since 2007. Lennox, a prominent AC manufacturer, had such a bad problem in the past with leaky evaporator coils that there was actually a class action lawsuit and settlement. Many of their consumers were experiencing refrigerant leaks within the first 3 to 5 years! Carrier experienced similar issues with their products in the past, seeing Freon leaks crop up within the first 5 to 7 years.

One could argue that when the Department of Energy raised the energy efficiency standards, this pushed the industry to thinner tubing, resulting in more evaporator coil leaks and more ozone-damaging Freon released into the atmosphere. The amount of electricity saved by moving from 10 SEER to 13 SEER is negated by the expense of premature evaporator coil replacement. But if copper is so susceptible to formicary corrosion, why hasn’t the industry found an alternative?

Aluminum Evaporator Coils – The Future of Avoiding Refrigerant Leaks

There have been numerous attempts to solve the formicary corrosion problem. Coatings such as blue epoxy or tin have been used to protect the copper. This has reduced the problem, but the coating is never perfect. If even a microscopic amount of the copper is exposed, it can result in a leaking evaporator coil.

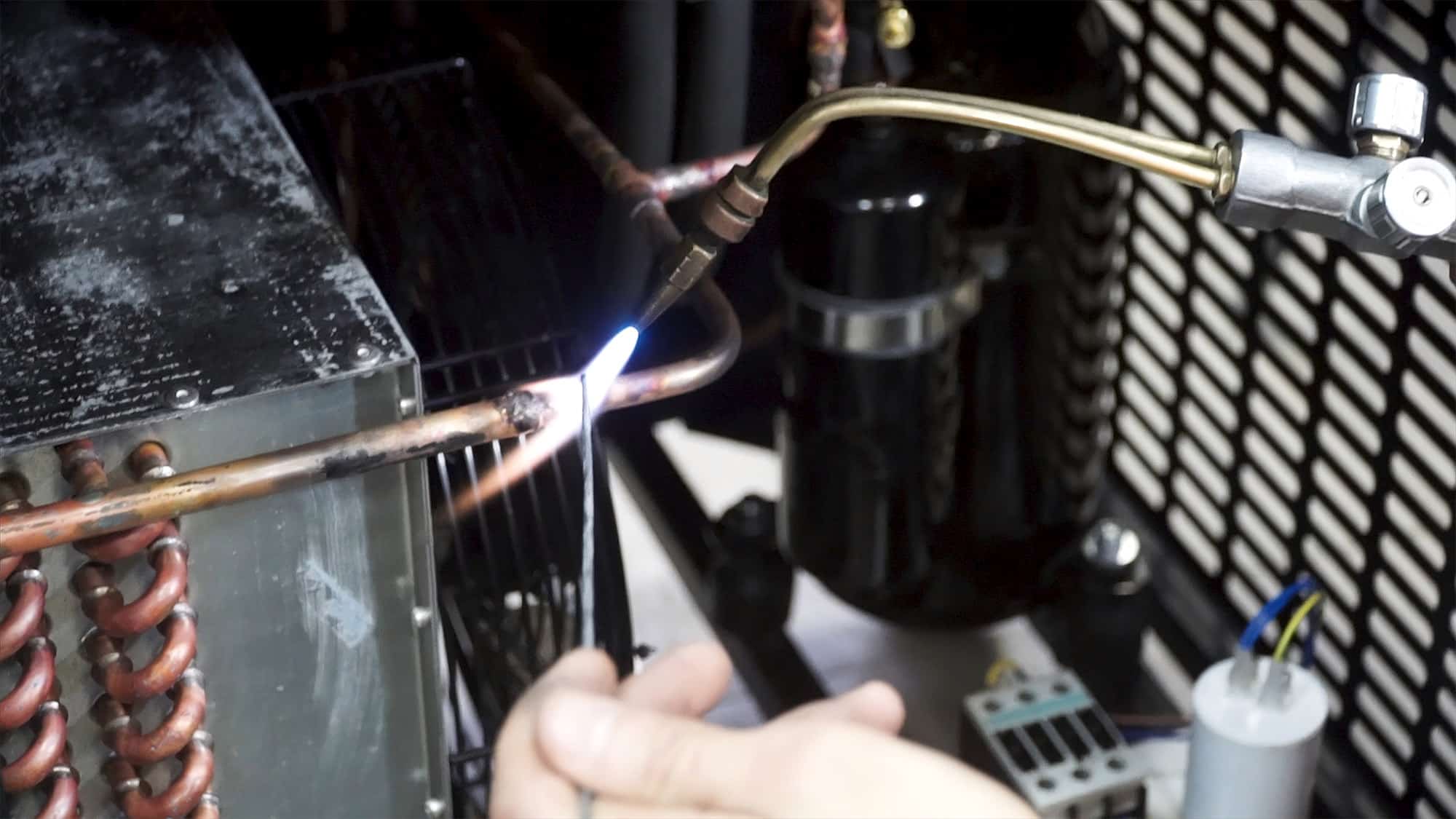

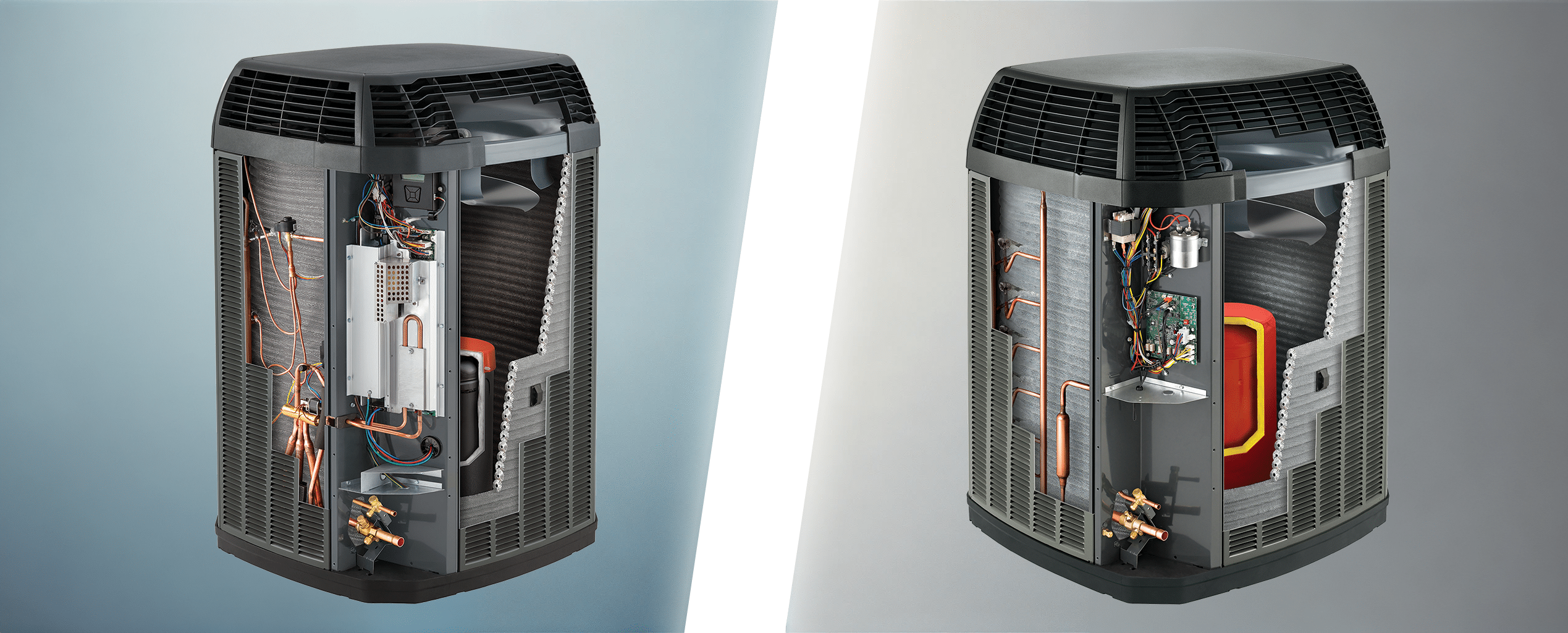

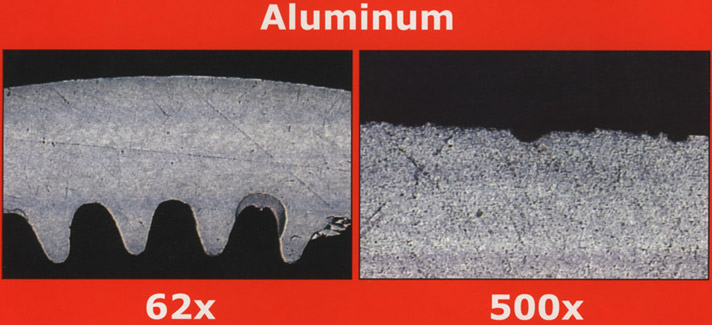

While aluminum is not susceptible to formicary corrosion or electrolysis, it does not transfer heat as well as copper. In addition, copper is easier to work with and is more malleable. To built an all-aluminum evaporator coil, the tube wall must be thicker and the entire evaporator coil larger. Trane solved these challenges by optimizing the geometry of the coil slabs and riflings inside the tubing. In addition they developed a very precise and automated process to braze the aluminum joints and tube ends.

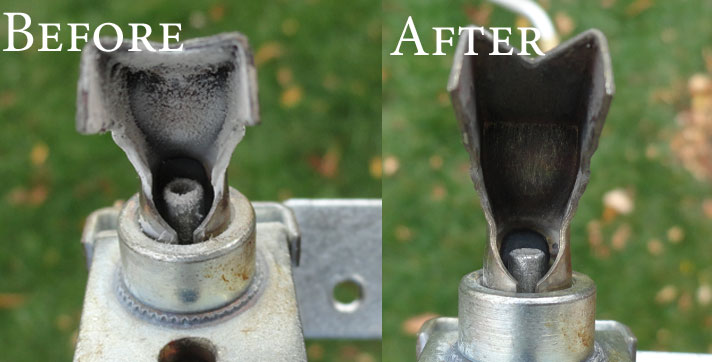

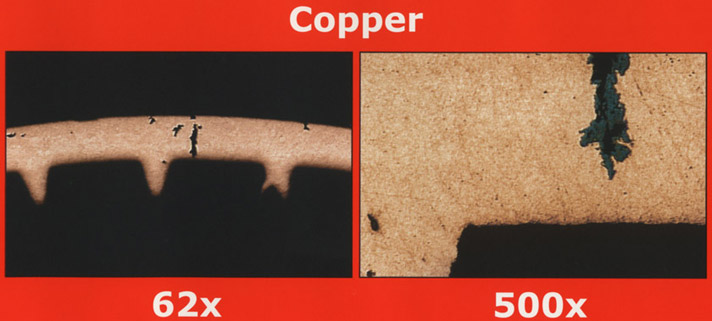

The photos below show the tube walls of a copper and an aluminum evaporator coil, both subjected to a formic acid corrosion test. You’ll notice that the aluminum is much thicker. This is necessary because of the difficulty of working with aluminum versus copper. You can also see multiple fissures in the copper while the aluminum is free of any cracks or holes. This make it easy to understand why thinner copper will spring a leak sooner. It’s amazing that the aluminum tubing is completely impervious!

In addition to formicary corrosion, copper evaporator coils experience electrolytic corrosion from the dissimilar metals. This happens because the connection of the copper tube and the aluminum fin form a sort of battery. Because all-aluminum AC unit coils use no dissimilar metals, they experience no electrolytic corrosion. The photo below compares an all-aluminum Trane evaporator coil on the left and a typical copper coil on the right after a 500-hour salt spray test. You can clearly see that Trane’s aluminum coil is essentially unaffected by the spray test. While the copper air conditioner coil has experienced significant corrosion.

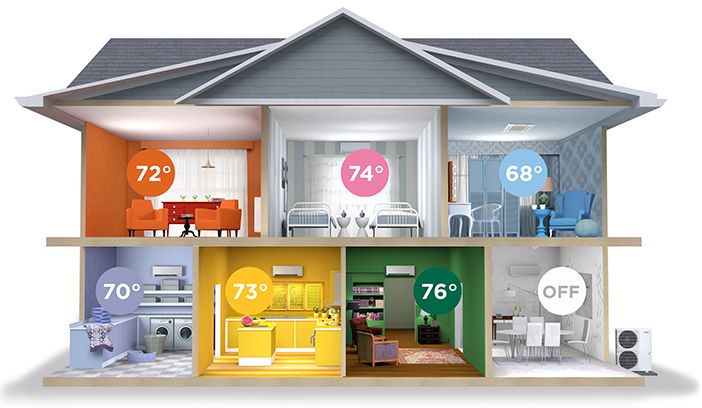

Since 2005, we’ve installed thousands of Trane air conditioners with aluminum coils, and we have yet to observe a single leak due to formicary corrosion. For about a decade, Trane was the only manufacturer of an all-aluminum coil, but, over the past few years, most manufacturers have adopted the aluminum coil. Today, most central air conditioners use aluminum evaporator coils while mini-splits and window units still use copper coils.

Can An Aluminum Evaporator Coil Leak?

So, with the new aluminum coils, there should be no more Freon leaks, right? Aluminum evaporator coils eliminate the number one cause of refrigerant leaks, but that doesn’t mean they will never leak. The reality is that Freon leaks can still happen in aluminum coils due to issues like manufacturing defects or physical damage.

Working with aluminum can be more challenging as it’s less malleable than copper. Brazing aluminum joints requires a very controlled heating process. If a manufacturer lacks proper automation and quality control, they could see a high failure rate in the many braze joints within an AC coil. This highlights the importance of buying an air conditioner from only a brand with a track record of quality and reliability.

Despite the industry’s shift to aluminum evaporator coils, nearly all manufacturers besides Trane still use copper-aluminum coils in the outdoor unit. Also, mini-split systems still use copper to this day due to their smaller size. Aluminum requires larger coils in order to achieve the same efficiency as copper, making it unsuitable for space-constrained installations. Check out this article about Trane’s exclusive Spine-Fin technology for condenser coils.

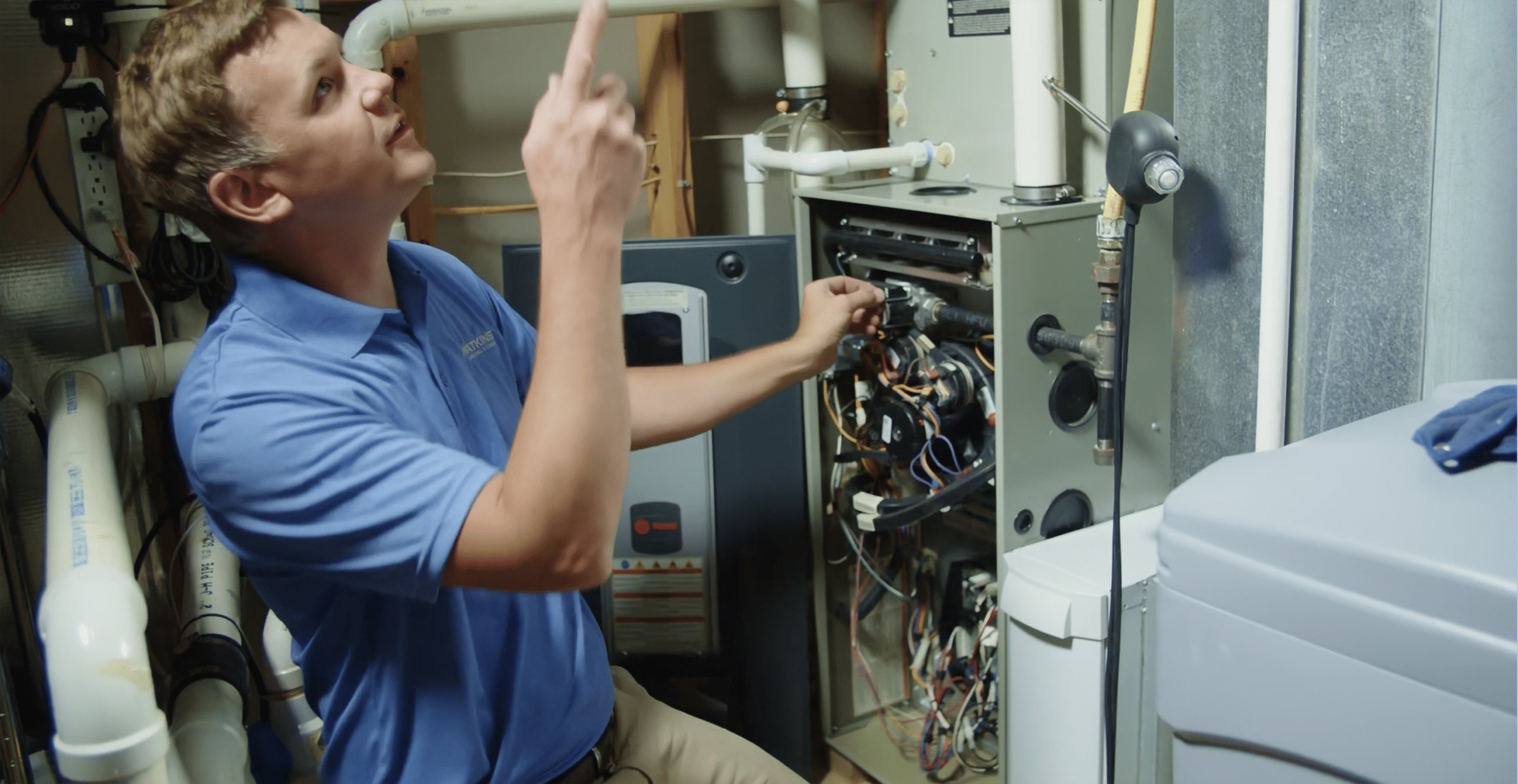

Strategies to Reduce Refrigerant Leaks

Hopefully, you’ve learned a few strategies to reduce to chance of an indoor refrigerant leak. Combining improved fresh air ventilation with an APCO UV air purifier will reduce VOCs in your home and lead to a longer-lasting AC unit or heat pump with fewer Freon leak headaches. Reach out to our Watkins Heating & Cooling professionals today. Let an expert HVAC technician safeguard your air conditioner from leaks in order to keep the cool air flowing and make your home’s air as comfortable and breathable as possible.